Earlier in the month, whilst attending an entire day's worth of seminars on 3-D imaging presented by the folks at Stemmer Imaging (Tongham, UK) our European correspondent overheard a couple of CEOs discussing the lack of talented young engineers who were entering the wonderful world of vision systems design.

As you might expect, the CEOs naturally felt that the low salaries offered by many of the Small to Medium Sized Enterprises that build vision systems for large OEM customers had a lot to do with it.

They believed that the first class engineering talent - in the UK at least - was still being attracted away from the engineering profession to enter less satisfying, yet ultimately more rewarding fields, such as investment banking.

While there may be some truth to that statement, I can't help but think that there's more to it than that. I think that the real problem is that manufacturers just haven't done much at all to make products that are affordable enough to allow children to experiment with hardware and software at an early age.

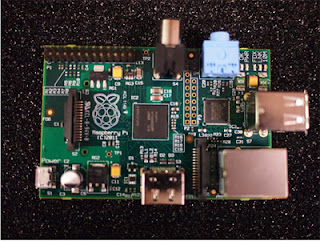

Well, I'm pleased to see that there are some folks out there who agree with me. More specifically, the folks at a Cambridge University (Cambridge, UK) based spinout called Raspberry Pi. The clever folks there have developed and are now selling a small $25 Arm (Cambridge, UK) based computer that into a TV and a keyboard and can be used by children (and interested adults!) as a means to learn programming.

The idea behind the tiny and cheap computer for kids came in 2006, when Eben Upton and his colleagues at the University of Cambridge’s Computer Laboratory (Cambridge, UK), including Rob Mullins, Jack Lang and Alan Mycroft, became concerned about the year-on-year decline in the numbers and skills levels of the A-Level students applying to read Computer Science in each academic year.

By 2008, processors designed for mobile devices were becoming more affordable, and powerful enough to deliver multimedia content, a feature the team felt would make the board desirable to kids who wouldn't initially be interested in a purely programming-oriented device.

Eben (now a chip architect at Broadcom), Rob, Jack and Alan, then teamed up with Pete Lomas at Norcott Technologies, and David Braben, co-author of the seminal BBC Micro game Elite, to form the Raspberry Pi Foundation, and the credit-card sized device was born.

This is a terrific idea and one which some of our esteemed colleagues who market both hardware and software for the vision systems business might like to consider emulating. What better way to encourage those young programmers to get hooked on vision systems design at an early age.

Friday, March 30, 2012

Tuesday, March 27, 2012

Covering all the bases

A few months back, I had the great pleasure of taking a little trip in my trusty motor vehicle to visit a company that has been solving problems in test and automation for more than 10 years. Indeed, during that time, the company has developed a plethora of systems thanks to its specialized technical knowledge of the vision systems business.

After interviewing the co-founder of the company for a couple of hours, I returned back to PennWell Towers to pen an article based on the design of a rather specialized, yet fascinating system that the engineers at the company had developed.

After the article had been finished, it was published in the pages of Vision Systems Design magazine. And the response from the readers was excellent. All thanks, in part at least, to the fact that the savvy Editor-In-Chief has a rather clever knack of identifying stories that will whet the appetite of you, our readers.

Fast forward a few months, and I'm now being asked by the powers that be at PennWell Corporation to suggest a suitable candidate who might be able to deliver a webcast for Vision Systems Design on a subject involving the development of a system similar to the one that I had written about earlier.

Absolutely convinced that the individual that I had interviewed for the magazine article would make a perfect candidate for such a web broadcast, I put his name forward. And, after several more weeks had passed, his presentation was broadcast on the Interweb.

The response to the presentation was as spectacular as the printed article had been. Indeed, after the presentation, the individual in question had several people email him to enquire whether he might be able to develop similar inspection systems for them. Needless to say, he was quite pleased by the whole affair to say the least and so was I.

For systems integrators who have identified particularly specialized markets and/or industries which they would like to target, there's a lesson to be learned here. Instead of just describing the capabilities on your web sites by written means, why not consider developing a web-based seminar on the story too?

Clearly, the effort is well worth the financial reward. And if you think that we here at Vision Systems Design can help you in such a venture, why not drop me an email?

After interviewing the co-founder of the company for a couple of hours, I returned back to PennWell Towers to pen an article based on the design of a rather specialized, yet fascinating system that the engineers at the company had developed.

After the article had been finished, it was published in the pages of Vision Systems Design magazine. And the response from the readers was excellent. All thanks, in part at least, to the fact that the savvy Editor-In-Chief has a rather clever knack of identifying stories that will whet the appetite of you, our readers.

Fast forward a few months, and I'm now being asked by the powers that be at PennWell Corporation to suggest a suitable candidate who might be able to deliver a webcast for Vision Systems Design on a subject involving the development of a system similar to the one that I had written about earlier.

Absolutely convinced that the individual that I had interviewed for the magazine article would make a perfect candidate for such a web broadcast, I put his name forward. And, after several more weeks had passed, his presentation was broadcast on the Interweb.

The response to the presentation was as spectacular as the printed article had been. Indeed, after the presentation, the individual in question had several people email him to enquire whether he might be able to develop similar inspection systems for them. Needless to say, he was quite pleased by the whole affair to say the least and so was I.

For systems integrators who have identified particularly specialized markets and/or industries which they would like to target, there's a lesson to be learned here. Instead of just describing the capabilities on your web sites by written means, why not consider developing a web-based seminar on the story too?

Clearly, the effort is well worth the financial reward. And if you think that we here at Vision Systems Design can help you in such a venture, why not drop me an email?

Friday, March 23, 2012

As clear as daylight

This month, a leading engineering integrator of robotic and machine vision systems and a fastening technology company announced they had joined forces to introduce robotic capabilities uniquely engineered for a fastener installation press.

According to a statement issued on behalf of the two companies, the partnership 'provides an unprecedented marketplace opportunity for completely hands-off installation of self-clinching fasteners using the newly developed robotic system.'

The statement goes on to say, that 'the robotic system developed for the fastening technology company is equipped to pick up, move, and position a work piece for alignment with holes where fasteners will be installed automatically by the press. After fastener installation, the robot removes the finished work piece and advances to the next job.'

The system -- apparently -- is offered in two standard packages to accommodate various work piece sizes. The turnkey system integrates a conveyor with locator, output conveyor, gripper, robot, and a basic sequence program to interface with the press. Among available robot options, a robot slide can be supplied to expand work cells for multiple presses.

The robotic system sounds like a step in the right direction for both companies. However, there's only one slight hitch. When Vision Systems Design contacted the leading engineering integrator of robotic and machine vision systems to discover whether or not the system had incorporated any interesting vision systems, we were informed that the system had not been built yet.

Clearly then, this is yet another of those common instances where overeager companies and their public relations firms have forgotten how to use the future tense, leaving their customers somewhat disappointed that they cannot obtain a system that they may believe has already been completed.

According to a statement issued on behalf of the two companies, the partnership 'provides an unprecedented marketplace opportunity for completely hands-off installation of self-clinching fasteners using the newly developed robotic system.'

The statement goes on to say, that 'the robotic system developed for the fastening technology company is equipped to pick up, move, and position a work piece for alignment with holes where fasteners will be installed automatically by the press. After fastener installation, the robot removes the finished work piece and advances to the next job.'

The system -- apparently -- is offered in two standard packages to accommodate various work piece sizes. The turnkey system integrates a conveyor with locator, output conveyor, gripper, robot, and a basic sequence program to interface with the press. Among available robot options, a robot slide can be supplied to expand work cells for multiple presses.

The robotic system sounds like a step in the right direction for both companies. However, there's only one slight hitch. When Vision Systems Design contacted the leading engineering integrator of robotic and machine vision systems to discover whether or not the system had incorporated any interesting vision systems, we were informed that the system had not been built yet.

Clearly then, this is yet another of those common instances where overeager companies and their public relations firms have forgotten how to use the future tense, leaving their customers somewhat disappointed that they cannot obtain a system that they may believe has already been completed.

Labels:

fastening,

machine vision,

robot,

vision systems design

Wednesday, March 21, 2012

Beetlecams capture wildlife up close

Keen to capture images of animals in their natural habitat in as up-close and personal manner as possible, a UK-based photographic team has taken it upon themselves to develop remote-controlled armored cameras.

The new cameras aren't the first of William and Matthew Burrard-Lucas' efforts to use imaging devices in such a fashion. In fact, it was three years ago when they first came up with the idea of embarking on a project to get unique close-up, ground level photographs of African wildlife.

To do just that, William Burrard-Lucas built the first of the so-called BeetleCams -- a remote controlled buggy with a DSLR camera mounted on top. They pair then travelled to Tanzania and used the buggy to capture photographs of elephants and buffalo. Sadly, however, the BeetleCam was almost destroyed in their only encounter with a lion.

Not entirely satisfied with their efforts, they went about developing lion-proof versions of the BeetleCam -- one with more advanced capabilities and one with an armored shell. They then returned to Africa in 2011 to photograph the lions of the Masai Mara. Once again, their BeetleCam received a battering, but it survived, and they came back with a portfolio of lion photographs that exceeded all their expectations.

And the development of the Beetlecam continues unabated, apparently. William Burrard-Lucas has now created a third generation of BeetleCam which has evolved to take into account the pairs' experiences from previous trips.

But the really good news is that these BeetleCam are now available to purchase by anyone that might also be inspired to take pictures of wildlife in a similar fashion. The bad news is that the starting price for a basic BeetleCam is GBP1,250, which is pretty close to $2000 give or take a few British shillings. Having said that, each of the BeetleCams is custom built to meet the requirements of the user.

The photography duo have stressed that their BeetleCams must be used responsibly. They urge those that might deploy one to respect the animals they are photographing and back off immediately if they think that the BeetleCam might be causing distress to the animals.

I'd buy one myself. But there just aren't enough wild animals in New Hampshire to make it all that worthwhile, unless one counts some of the folks that frequent some of the local watering holes on a Friday night, that is. And I couldn't promise that taking pictures of such people might cause a considerable amount of distress either.

The new cameras aren't the first of William and Matthew Burrard-Lucas' efforts to use imaging devices in such a fashion. In fact, it was three years ago when they first came up with the idea of embarking on a project to get unique close-up, ground level photographs of African wildlife.

To do just that, William Burrard-Lucas built the first of the so-called BeetleCams -- a remote controlled buggy with a DSLR camera mounted on top. They pair then travelled to Tanzania and used the buggy to capture photographs of elephants and buffalo. Sadly, however, the BeetleCam was almost destroyed in their only encounter with a lion.

Not entirely satisfied with their efforts, they went about developing lion-proof versions of the BeetleCam -- one with more advanced capabilities and one with an armored shell. They then returned to Africa in 2011 to photograph the lions of the Masai Mara. Once again, their BeetleCam received a battering, but it survived, and they came back with a portfolio of lion photographs that exceeded all their expectations.

And the development of the Beetlecam continues unabated, apparently. William Burrard-Lucas has now created a third generation of BeetleCam which has evolved to take into account the pairs' experiences from previous trips.

But the really good news is that these BeetleCam are now available to purchase by anyone that might also be inspired to take pictures of wildlife in a similar fashion. The bad news is that the starting price for a basic BeetleCam is GBP1,250, which is pretty close to $2000 give or take a few British shillings. Having said that, each of the BeetleCams is custom built to meet the requirements of the user.

The photography duo have stressed that their BeetleCams must be used responsibly. They urge those that might deploy one to respect the animals they are photographing and back off immediately if they think that the BeetleCam might be causing distress to the animals.

I'd buy one myself. But there just aren't enough wild animals in New Hampshire to make it all that worthwhile, unless one counts some of the folks that frequent some of the local watering holes on a Friday night, that is. And I couldn't promise that taking pictures of such people might cause a considerable amount of distress either.

Labels:

BeetleCam,

camera,

elephants,

vision systems design,

wildlife

Friday, March 16, 2012

3-D image processing relieves male shoppers from drudgery

Most of the ladies that I've met in my life enjoy shopping for clothes. Most men, on the other hand, would seem to absolutely despise it. In fact, there's only one thing that men dislike more than shopping for clothes for themselves, and that's accompanying their significant other to purchase a new pair of jeans or a pretty frock.

According to a straw poll taken among some of my closest male friends, the reason for this is the endless amount of time such shopping sprees take. Naturally, this is because of the fact that while two people might be the same height and wear the same size, the way their clothing fits their bodies can vary dramatically. As a result, up to 40 percent of clothing purchased both online and in person is returned because it doesn't fit properly.

Now, however, thanks to the power of Microsoft's (Redmond, WA) Kinect, those hours of waiting for your partner as she spends time in the changing room of the local department store might soon become a thing of the past.

That's right! Much to the relief of menfolk worldwide, a London, UK-based outfit called Bodymetrics has taken eight of the Kinect for Windows sensors and integrated them into a 3-D body-mapping system 3-D body-mapping system called the Bodymetrics Pod, a system that was recently introduced to American shoppers during "Women's Denim Days" at Bloomingdale's in Century City, Los Angeles, CA.

During Bloomingdale's Denim Days, held between the 15 to the 18 March, customers are able to get their body mapped and also become a Bodymetrics member. The free service enables customers to access an online account and order jeans based on their body shape. But the best thing of all must surely be the fact that the entire body-mapping process takes less than 5 seconds!

As a taster of future things to come, customers will also be able to virtually see how jeans look on their body -- whether they are too tight, too loose, or just a perfect fit.

Helping women shop for jeans in department stores is just the start of what Bodymetrics envisions for its body-mapping technologies. The company is working on a solution that can be used at home too. By using that, individuals will be able to scan their body and then go online to select, virtually try on, and purchase clothing that matches their body shape. So soon, there may be no need to leave the house either!

Those interested in 3-D body mapping might be interested to know that there is an entire conference dedicated to this fascinating subject. "3D Body Scanning Technologies" takes place every year in October in Lugano, Swizerland.

According to a straw poll taken among some of my closest male friends, the reason for this is the endless amount of time such shopping sprees take. Naturally, this is because of the fact that while two people might be the same height and wear the same size, the way their clothing fits their bodies can vary dramatically. As a result, up to 40 percent of clothing purchased both online and in person is returned because it doesn't fit properly.

Now, however, thanks to the power of Microsoft's (Redmond, WA) Kinect, those hours of waiting for your partner as she spends time in the changing room of the local department store might soon become a thing of the past.

That's right! Much to the relief of menfolk worldwide, a London, UK-based outfit called Bodymetrics has taken eight of the Kinect for Windows sensors and integrated them into a 3-D body-mapping system 3-D body-mapping system called the Bodymetrics Pod, a system that was recently introduced to American shoppers during "Women's Denim Days" at Bloomingdale's in Century City, Los Angeles, CA.

During Bloomingdale's Denim Days, held between the 15 to the 18 March, customers are able to get their body mapped and also become a Bodymetrics member. The free service enables customers to access an online account and order jeans based on their body shape. But the best thing of all must surely be the fact that the entire body-mapping process takes less than 5 seconds!

As a taster of future things to come, customers will also be able to virtually see how jeans look on their body -- whether they are too tight, too loose, or just a perfect fit.

Helping women shop for jeans in department stores is just the start of what Bodymetrics envisions for its body-mapping technologies. The company is working on a solution that can be used at home too. By using that, individuals will be able to scan their body and then go online to select, virtually try on, and purchase clothing that matches their body shape. So soon, there may be no need to leave the house either!

Those interested in 3-D body mapping might be interested to know that there is an entire conference dedicated to this fascinating subject. "3D Body Scanning Technologies" takes place every year in October in Lugano, Swizerland.

Wednesday, March 14, 2012

Bag drop-off made easier with vision

There's nothing our European Editor likes more each year than taking a couple of weeks or more away from the hustle and bustle of work to spend his time loafing around in France's sunshine playground and enjoying fine wine and delicious food.

The trouble is, he does not much care for the journey to get there, nor the journey back. The UK airports are crowded affairs, you see, and boarding a plane often entails waiting in very long lines before one can obtain a boarding pass and check in one's bags.

However, thanks to a rather innovative system developed by Netherlands-based BagDrop (Rotterdam, the Netherlands), our European Editor's personal issues at the airport might finally be a thing of the past.

The new BagDrop systems looks set to make it easier for passengers to check in for a flight, obtain a boarding pass, as well as drop off their luggage, all without the need for any involvement from airport personnel.

Using the system, a passenger is first identified through the use of a scanner that can read passports and barcodes from flight confirmation documents e-mailed by airlines, after which flight details are verified. The passenger is then issued with a boarding pass and a barcode label that must be affixed to his or her bag.

In the next step, the bag is deposited into the BagDrop unit, which then checks the barcode to determine whether it was the same one that was printed for the passenger. In addition to calculating the volume of the bag using a 3-D imaging system, the system also measures a number of other parameters, including the bag weight, dimensions, and shape to determine whether or not it can be conveyed by the system. For liability reasons, it also captures an image of the exterior of the bag.

Once the bag has been accepted by the system, it then prints a claim tag that passengers can use to verify the identity of the bag upon arrival at their final destination.

The BagDrop system is already up and running at Schiphol Airport where it has already processed thousands of passengers. Unfortunately, our European Editor hasn't seen any of the systems at Heathrow airport yet, so he's still going to have to wait in a long line to take his next holiday flight to France. That's if I allow him to take any holiday this year.

The trouble is, he does not much care for the journey to get there, nor the journey back. The UK airports are crowded affairs, you see, and boarding a plane often entails waiting in very long lines before one can obtain a boarding pass and check in one's bags.

However, thanks to a rather innovative system developed by Netherlands-based BagDrop (Rotterdam, the Netherlands), our European Editor's personal issues at the airport might finally be a thing of the past.

The new BagDrop systems looks set to make it easier for passengers to check in for a flight, obtain a boarding pass, as well as drop off their luggage, all without the need for any involvement from airport personnel.

Using the system, a passenger is first identified through the use of a scanner that can read passports and barcodes from flight confirmation documents e-mailed by airlines, after which flight details are verified. The passenger is then issued with a boarding pass and a barcode label that must be affixed to his or her bag.

In the next step, the bag is deposited into the BagDrop unit, which then checks the barcode to determine whether it was the same one that was printed for the passenger. In addition to calculating the volume of the bag using a 3-D imaging system, the system also measures a number of other parameters, including the bag weight, dimensions, and shape to determine whether or not it can be conveyed by the system. For liability reasons, it also captures an image of the exterior of the bag.

Once the bag has been accepted by the system, it then prints a claim tag that passengers can use to verify the identity of the bag upon arrival at their final destination.

The BagDrop system is already up and running at Schiphol Airport where it has already processed thousands of passengers. Unfortunately, our European Editor hasn't seen any of the systems at Heathrow airport yet, so he's still going to have to wait in a long line to take his next holiday flight to France. That's if I allow him to take any holiday this year.

Friday, March 9, 2012

Track your beer with a QR code

Originally invented by Toyota subsidiary Denso Wave back in 1994 to track vehicles during manufacturing, the QR code has now become popular outside the automobile industry thanks to the prevalence of intelligent handheld devices such as smart phones equipped with inexpensive image sensors.

One of the latest companies to use the code in a rather innovative way is the US beer giant Anheuser-Busch. It has recently started to print the QR codes on Budweiser packaging to allow consumers to trace the origins of the beer they hold in their hands back to one of the company's 12 US breweries.

Yes, that's right. By using a smart phone equipped with a free "Track Your Bud" app, beer drinkers across the US can now scan the QR code on their Budweisers, enter the "Born On" date found on bottles and cans, and be taken on a guided tour of the creation of their individual beer by the Budweiser brewmaster responsible for it.

The "Track Your Bud" app provides beer drinkers with an insight into the source and selection of ingredients for the beer, Budweiser's seven-step brewing process, when their beer began beechwood aging and which brewmaster tasted it multiple times throughout its brew cycle to ensure it met Budweiser's standards.

"Track Your Bud also gives consumers insight into where Budweiser's raw materials come from -- including barley farms in Idaho, Montana, North Dakota, Minnesota, and Wisconsin; and hops farms in Idaho, Washington, Oregon, and Germany," says Jane Killebrew-Galeski, director of brewing, quality, and innovation for Anheuser-Busch.

While the inventors of the QR code may never have dreamt that the technology that they developed all those years ago would ever be put to such innovative uses, this is clearly the wave of the future.

Indeed, I can't wait until the day when all companies follow the responsible lead set by the US brewing giant. Enabling consumers to trace the origins of the products they purchase directly back to the specific individuals at the company that made them will allow them to see exactly who to contact should anything go wrong.

For more information about the new Budweiser "Track Your Bud" program, check out www.TrackYourBud.com or download the app.

Bottoms up!

One of the latest companies to use the code in a rather innovative way is the US beer giant Anheuser-Busch. It has recently started to print the QR codes on Budweiser packaging to allow consumers to trace the origins of the beer they hold in their hands back to one of the company's 12 US breweries.

Yes, that's right. By using a smart phone equipped with a free "Track Your Bud" app, beer drinkers across the US can now scan the QR code on their Budweisers, enter the "Born On" date found on bottles and cans, and be taken on a guided tour of the creation of their individual beer by the Budweiser brewmaster responsible for it.

The "Track Your Bud" app provides beer drinkers with an insight into the source and selection of ingredients for the beer, Budweiser's seven-step brewing process, when their beer began beechwood aging and which brewmaster tasted it multiple times throughout its brew cycle to ensure it met Budweiser's standards.

"Track Your Bud also gives consumers insight into where Budweiser's raw materials come from -- including barley farms in Idaho, Montana, North Dakota, Minnesota, and Wisconsin; and hops farms in Idaho, Washington, Oregon, and Germany," says Jane Killebrew-Galeski, director of brewing, quality, and innovation for Anheuser-Busch.

While the inventors of the QR code may never have dreamt that the technology that they developed all those years ago would ever be put to such innovative uses, this is clearly the wave of the future.

Indeed, I can't wait until the day when all companies follow the responsible lead set by the US brewing giant. Enabling consumers to trace the origins of the products they purchase directly back to the specific individuals at the company that made them will allow them to see exactly who to contact should anything go wrong.

For more information about the new Budweiser "Track Your Bud" program, check out www.TrackYourBud.com or download the app.

Bottoms up!

Labels:

QR code,

smart phone app,

vision systems design

Thursday, March 8, 2012

The problem with vision

It's a common phrase amongst those folks in the Vision Systems Design world that the first five years in the business are the hardest.

Now the reason for this is quite simple. To effectively build a vision system for a particular customer demands that an engineer at a system integrator must have a wealth of experience at his or her disposal.

That's because vision systems aren't trivial to build. System integrators must first gain a very detailed understanding of the specific inspection task that needs to be performed by the system before they even go near a keyboard to use their knowledge in specifying the hardware and software that may be suitable for the job.

Now while the system integrator is usually well aware of the specific set of questions that he needs to ask his potential customer before embarking on a project, oftentimes the customer in question will have no idea why he is asking them.

That's because the hardware and the software that might be needed for such a system are highly dependent on a number of factors that the customer may not realize are vitally important considerations.

So what tends to happen is that -- in some instances at least -- the system integrator gets involved in an exercise that is almost as painful as extracting teeth from the potential customer before he can get to work developing a system.

Usually, of course, after the specifics of the inspection and the conditions under which a component must operate have been determined, it's plain sailing -- but not always.

Finally understanding the capabilities of the vision system, the customer may then decide that he or she could potentially extend these capabilities to capture even more data from such a system, which could be used elsewhere in his or her production process.

The hapless system integrator may be then called upon to modify a system that is almost completed to perform a bunch of additional tasks for which it wasn't initially intended.

Needless to say, this all costs money. And while most system integrators are happy to make an additional buck for such work, they do so while cursing the customer for not thinking things through at the outset.

Now it would be wonderful if it were possible to create a generic template of questions that system integrators could ask their customers to fill out prior to any initial meeting, a move that could avoid any potential strife.

Unfortunately, due to the highly application-specific nature of the vision systems game, I don't really believe that's a viable option. Unless we can create an artificial intelligence (AI) system to extract the experience from those with years of industry background. Surely that would be a worthy goal for any of our imaging and vision associations to have a crack at producing.

Now the reason for this is quite simple. To effectively build a vision system for a particular customer demands that an engineer at a system integrator must have a wealth of experience at his or her disposal.

That's because vision systems aren't trivial to build. System integrators must first gain a very detailed understanding of the specific inspection task that needs to be performed by the system before they even go near a keyboard to use their knowledge in specifying the hardware and software that may be suitable for the job.

Now while the system integrator is usually well aware of the specific set of questions that he needs to ask his potential customer before embarking on a project, oftentimes the customer in question will have no idea why he is asking them.

That's because the hardware and the software that might be needed for such a system are highly dependent on a number of factors that the customer may not realize are vitally important considerations.

So what tends to happen is that -- in some instances at least -- the system integrator gets involved in an exercise that is almost as painful as extracting teeth from the potential customer before he can get to work developing a system.

Usually, of course, after the specifics of the inspection and the conditions under which a component must operate have been determined, it's plain sailing -- but not always.

Finally understanding the capabilities of the vision system, the customer may then decide that he or she could potentially extend these capabilities to capture even more data from such a system, which could be used elsewhere in his or her production process.

The hapless system integrator may be then called upon to modify a system that is almost completed to perform a bunch of additional tasks for which it wasn't initially intended.

Needless to say, this all costs money. And while most system integrators are happy to make an additional buck for such work, they do so while cursing the customer for not thinking things through at the outset.

Now it would be wonderful if it were possible to create a generic template of questions that system integrators could ask their customers to fill out prior to any initial meeting, a move that could avoid any potential strife.

Unfortunately, due to the highly application-specific nature of the vision systems game, I don't really believe that's a viable option. Unless we can create an artificial intelligence (AI) system to extract the experience from those with years of industry background. Surely that would be a worthy goal for any of our imaging and vision associations to have a crack at producing.

Friday, March 2, 2012

A European look at 3-D imaging

Interest in 3-D imaging has never been greater. Everyone, it seems, is interested in knowing what applications this technology might help solve.

So when I heard that the good folks at Stemmer Imaging (Tongham, UK) were putting on an entire day's worth of seminars on the subject at Mercedes-Benz World in Weybridge (located in Surrey, England), I instructed our European correspondent to scream down there in his old Honda Civic to check things out.

Now you might think that folks who develop systems to inspect paper towels, examine the surfaces of women's skin, or scrutinize the tread on skis wouldn't have much in common. But our assiduous European editor discovered differently at the event.

That's right. At one particular seminar presented by Christian Benderoth, the sales manager of GFMesstechnik (Berlin, Germany), he discovered that manufacturers of all these products are using a rather nifty little handheld 3-D image scanner to inspect the surfaces of their products.

The product in question -- which has been developed by GFMesstechnik -- is called the MikroCADlite. It is, in essence, a small scanner that uses a digital light projector (DLP) from Texas Instruments (Dallas, TX, USA) to project a structured light pattern onto a surface. The images are captured by an imager in the scanner, then analyzed to reveal the details of surfaces.

According to Benderoth, folks that make kitchen rolls embossed with aesthetically pleasing structures have used the scanner to produce color-coded height images of the embossed paper, in a move that allows them to check the consistency of the pattern. Their counterparts in the cosmetics business have created maps of the surface of skin around women's eyes to ascertain the before and after effects of cosmetics such as anti-aging cream. Not to be left out, engineers developing skis are using the system to capture 3-D images from which they can produce plots of the variation in tread across the bottom of a ski.

After the presentation, our European Editor decided to see what literature he could pick up on the MikroCADlite system to take home and read during what little leisure time he has left after he's finished working on the Vision System Design magazine and web site.

While flipping through the page of the document back home, he discovered that the MikroCADlite system had also been put to use examining the decor of the interior of car parts too. More specifically, at the back of the document there was a comparison between the decor of a 2005 BMW and a Honda Civic not entirely dissimilar to his own (see image).

Now, of course, the sorry old fool is trying desperately to interpret the images to discover whether his UK-made Honda car has a superior interior finish to its German counterpart. It's the last time I send him anywhere.

So when I heard that the good folks at Stemmer Imaging (Tongham, UK) were putting on an entire day's worth of seminars on the subject at Mercedes-Benz World in Weybridge (located in Surrey, England), I instructed our European correspondent to scream down there in his old Honda Civic to check things out.

Now you might think that folks who develop systems to inspect paper towels, examine the surfaces of women's skin, or scrutinize the tread on skis wouldn't have much in common. But our assiduous European editor discovered differently at the event.

That's right. At one particular seminar presented by Christian Benderoth, the sales manager of GFMesstechnik (Berlin, Germany), he discovered that manufacturers of all these products are using a rather nifty little handheld 3-D image scanner to inspect the surfaces of their products.

The product in question -- which has been developed by GFMesstechnik -- is called the MikroCADlite. It is, in essence, a small scanner that uses a digital light projector (DLP) from Texas Instruments (Dallas, TX, USA) to project a structured light pattern onto a surface. The images are captured by an imager in the scanner, then analyzed to reveal the details of surfaces.

According to Benderoth, folks that make kitchen rolls embossed with aesthetically pleasing structures have used the scanner to produce color-coded height images of the embossed paper, in a move that allows them to check the consistency of the pattern. Their counterparts in the cosmetics business have created maps of the surface of skin around women's eyes to ascertain the before and after effects of cosmetics such as anti-aging cream. Not to be left out, engineers developing skis are using the system to capture 3-D images from which they can produce plots of the variation in tread across the bottom of a ski.

After the presentation, our European Editor decided to see what literature he could pick up on the MikroCADlite system to take home and read during what little leisure time he has left after he's finished working on the Vision System Design magazine and web site.

While flipping through the page of the document back home, he discovered that the MikroCADlite system had also been put to use examining the decor of the interior of car parts too. More specifically, at the back of the document there was a comparison between the decor of a 2005 BMW and a Honda Civic not entirely dissimilar to his own (see image).

Now, of course, the sorry old fool is trying desperately to interpret the images to discover whether his UK-made Honda car has a superior interior finish to its German counterpart. It's the last time I send him anywhere.

Subscribe to:

Posts (Atom)